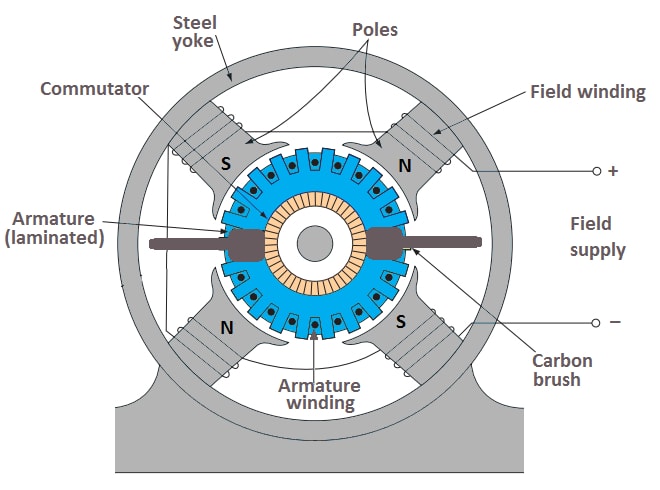

It can be built with the annealed steel laminations for reducing the power drop because of the eddy currents. In this type of DC machine the field winding is connected in parallel with the armature winding.

Construction Of A Dc Generator Explanation Of Its Various Parts Circuit Globe

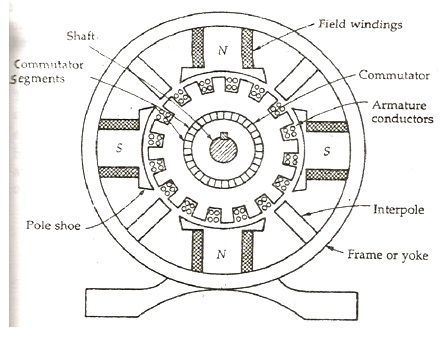

Design of Field Poles Field Coils Design of Commutator Brushes Magnetic circuit The path of magnetic flux is called magnetic circuit Magnetic circuit of dc machine comprises of yoke poles airgap armature teeth and armature core Flux produced by field coils emerges from N pole and cross the air gap to enter the armature tooth.

. Whenever field winding is energized then the pole gives magnetic flux. Design of the field System. Normally 70 of the rotor is slotted and remaining portion is unslotted in order to form the pole.

Construction of DC Machine Generator Motor 1. The four most common methods are. Magnetic Field System of DC Generator The Magnetic Field System is the stationary or fixed part of the machine.

It produces the main magnetic flux. Electrical Machines and Drives Third Edition 1996. Basic principles of the DC shunt motor _____ 5.

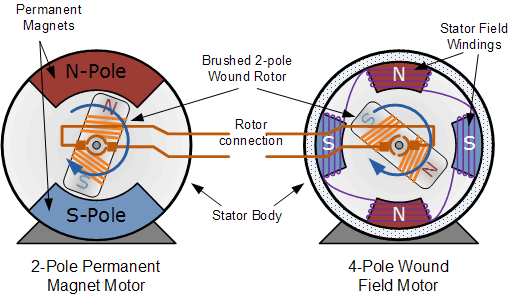

Many modern DC machines are constructed with a permanent magnet PM field which results in a constant flux. Separately-excited shunt-connected series-connected and compound. The modular design of the training system allows for applications which go above and beyond the.

The part of pole that is close to rotor distributes the flux on the surface of the rotor is known as pole shoes. A 5 kW 400 V 4 pole 1500 rpm DC shunt generator has the average flux density in the airgap as 12 Wbm 2 and the specific electric loading is 21000 Am. Describe the procedure for design of interpoles of DC machine.

The magnetic field system consists of Mainframe or Yoke Pole core and Pole shoes and Field or Exciting coils. Describe the procedure for design of field system of DC machine. Find the main dimensions of the machine if it has to.

Pole Cores and Pole Shoes. The coils cut the magnetic lines of forces to induce an EMF. Systems the generators and motors are all connected in series in one circuit.

This induced Emf develops current in the armature winding. The field winding of DC motor are made with field coils copper wire wound over the slots of the pole shoes in such a manner that when field current flows through it then adjacent poles have opposite polarity are produced. A state feedback gain matrix is designed for the dc motor with the help of pole-placement technique.

In case of turbo alternators the rotor windings or the field windings are distributed in the rotor slots. In a PM DC machine the armature circuit model is the complete circuit model and kphi is constant. The direction of this current in DC generators can be observed through the rule of Flemings Right-hand.

Wound-field dc motors are usually classified by shunt-wound series-wound and compound-wound. The pole of the DC machine is an electromagnet and the field winding is winding among pole. In a DC generator when the coil placed in the magnetic field is rotated by means of a prime mover or any handle.

The separately-excited machine has no physical connection between the field and armature windings. Of dc motor using state space approach. The field magnets consist of pole cores.

In stator of dc machine there is a frame that provides protection and support to internal structure from external environment in this frame there are poles that produce field at the stator. These various parts of DC Generator are described below in detail. It provides mechanical support for the poles and acts as a protecting cover for the whole.

Because of the parallel connection full voltage is applied to the field winding. Machine a torque angle of 90 is the normal condition with field and armature mmfs maintained in quadrature by the angular-position switching action of brushes and commutator. DC motors are described by the method used to excite the field.

Basic principles of 3-phase machines In the field of drive technology DC drives currently play a major role in mobile drive solutions. The rotor construction of the turbo alternator is as shown in fig. The current flow through the field winding is very small.

In the parallel-connected-system all generators and motors are arranged in parallel. The performance of dc motor under various conditions is simulated using MATLABSIMULINK environment and simulation result demonstrates the feasibility of the proposed system. Magnetic Frame and Yoke.

In addition to these permanent-magnet and brushless types are also available normally. In both cases the speed and direction of rotation of the motors is changed by varying the generator and motor excitations as shown in Figure 4612. Therefore shunt winding is designed with a large number of turns with high resistance.

Program to Design a series connected DC machine Number of conductors per parallel path 110 Hence mean emf induced per conductor 41818 Average Flux density Bav 06847 Diameter D of the other machine 07620 Length L of the other machine 02793 Number of conductors per parallel path 90. We will consider three basic types of DC machine where the operation is dependent on a field winding. Each circuit is excited from its own power supply.

The materials used for this are cast steel cast iron otherwise pole core. Overview of direct current machines _____ 3 Exercise 1.

Working Of Dc Generator With Its Construction And Types Electrical Wiring Colours Generator Wind Generator

Construction Of Dc Machine Generator Motor

Construction Of Dc Machines The Engineering Knowledge

Construction Of Dc Motor Parts Images Electrical4u

Dc Motor What Is It How Does It Work Types Uses

Dc Motor Diagram Motor Mechanical Energy Flower Background Design

0 comments

Post a Comment